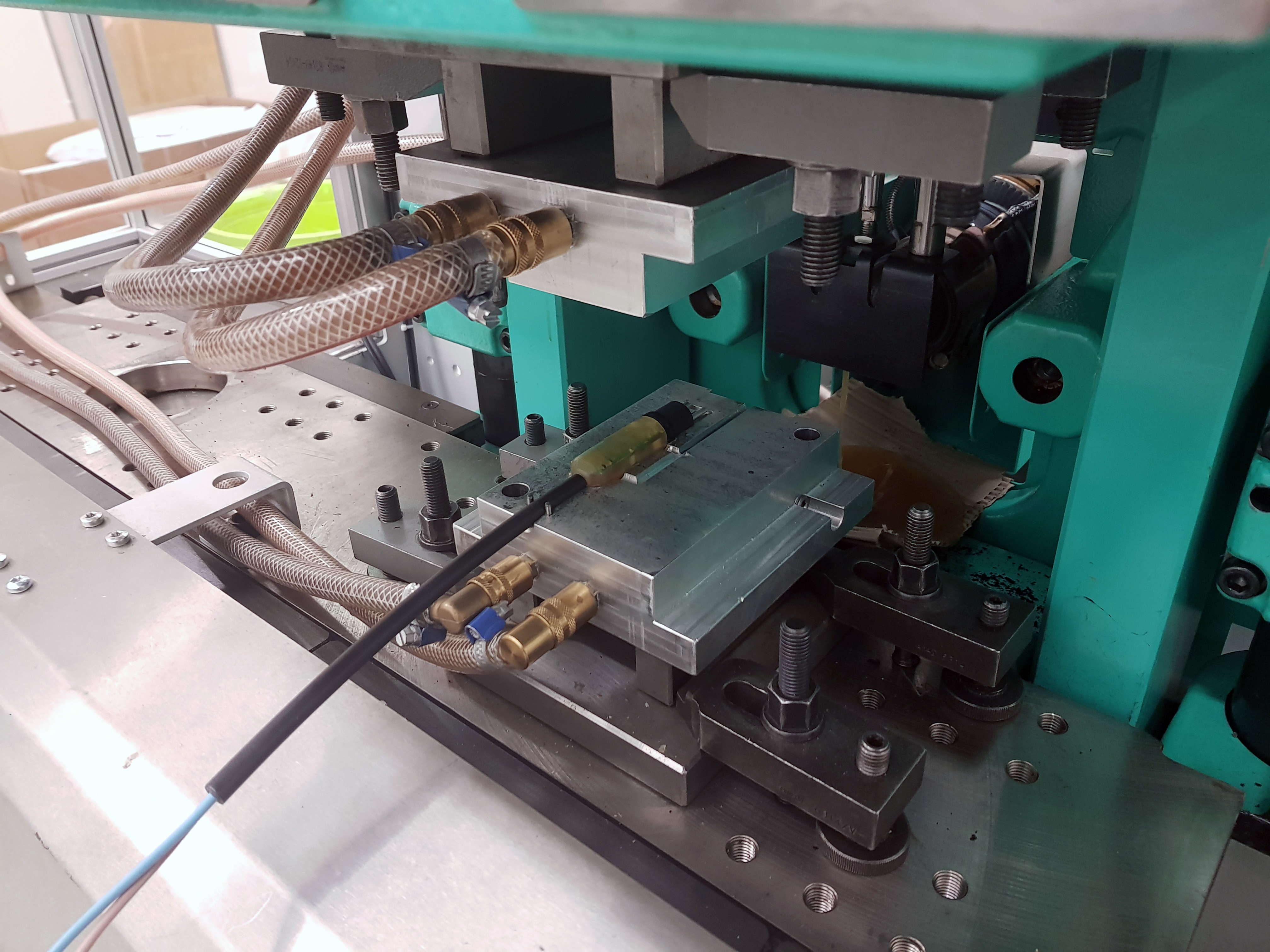

Over molding (a.k.a. encapsulation or insert molding) is the precision plastic injection molding process, where one material is molded over another material, like a cable adapter or transformer coil core. This way wide scale of power electronics and cable assemblies can be encapsulated, sealed and protected.

BENEFITS

Over molding is an ideal mess-free and high throughput alternative to conventional potting.

Low-pressure molding is a process to encapsulate and protect electronics from the environment. In three easy steps (insert-mold-test), even the most sensitive electronics and PCBs can be encapsulated, sealed and protected. All excess material and scrap can be reused.

BENEFITS

Like over molding, low-pressure molding is an ideal mess-free and high throughput alternative to conventional potting.

+358 (0)20 198 0190